Description

Product Description

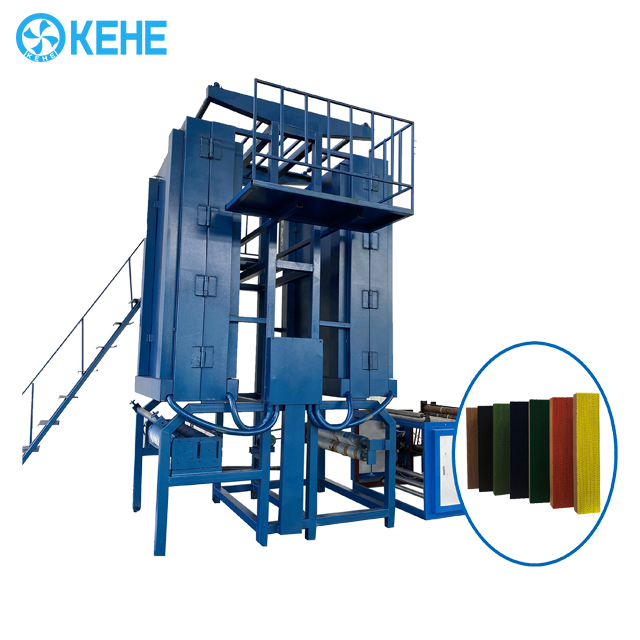

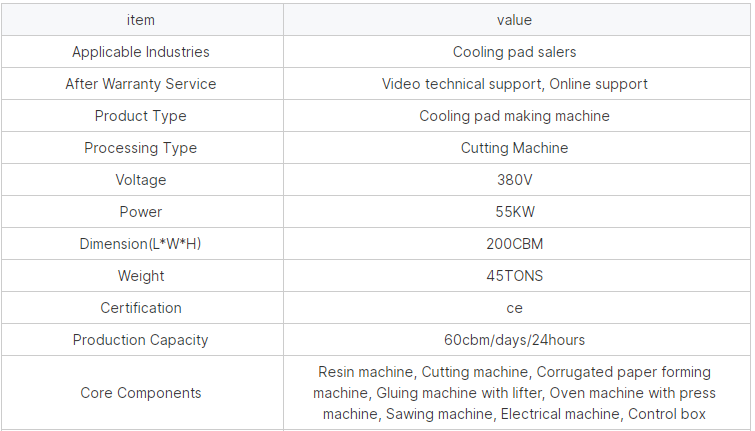

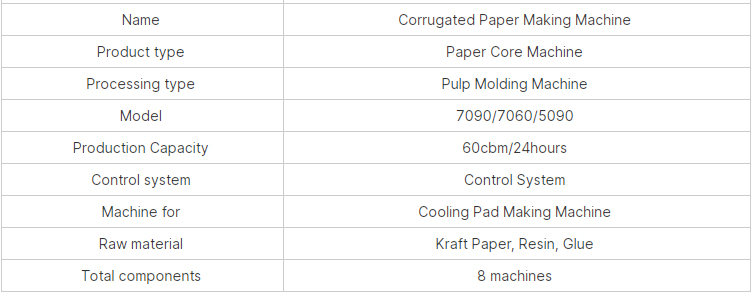

"General view of cooling pad production line. The production line covers an area of 200cbm.

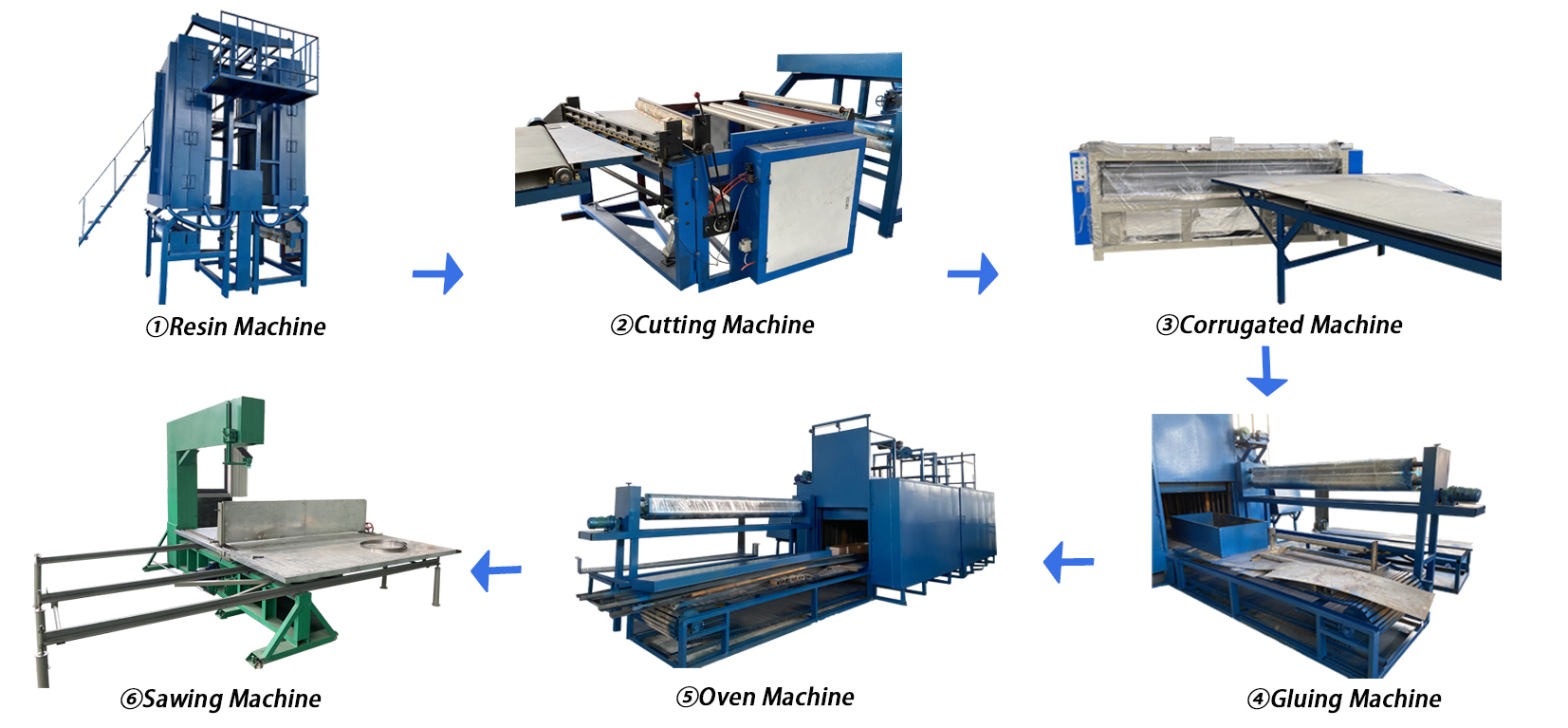

Above is all the machines and process for cooling pads production .

This production line need total 5 workers and 1 group leader who control all production line.

The final output capacity of cooling pads is 60cbm per day with 24 hours, one tons paper can output 54/46cbm cooling pads."

Detailed Images

| 1.Resin Machine | ||||||||

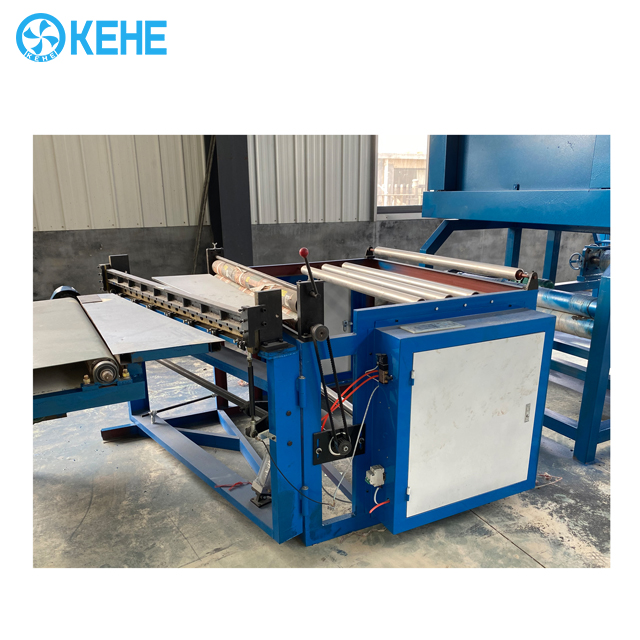

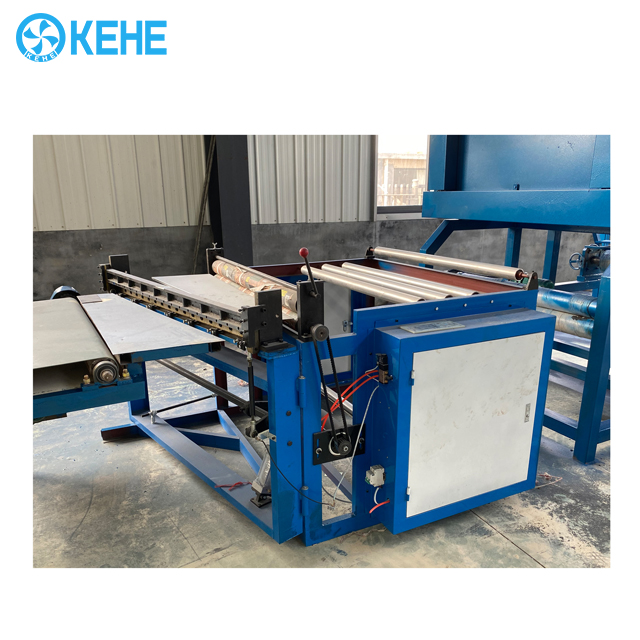

2.Cutting Machine |  | ||||||||

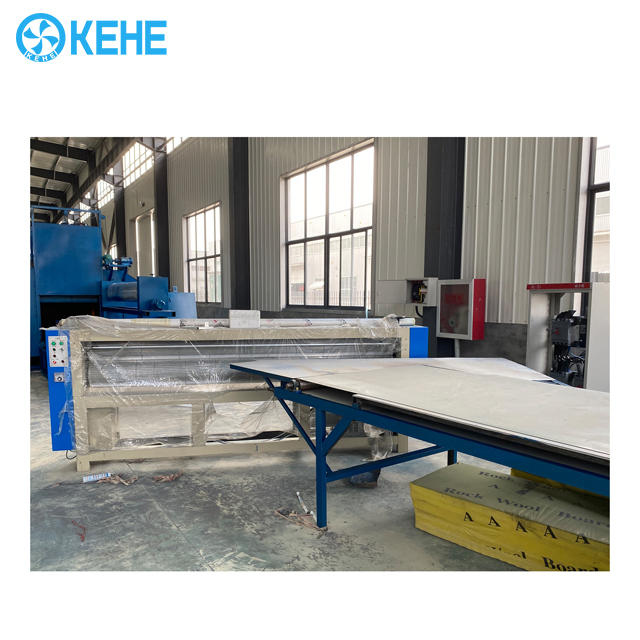

| 3.Corrugated Paper Forming Machine | ||||||||

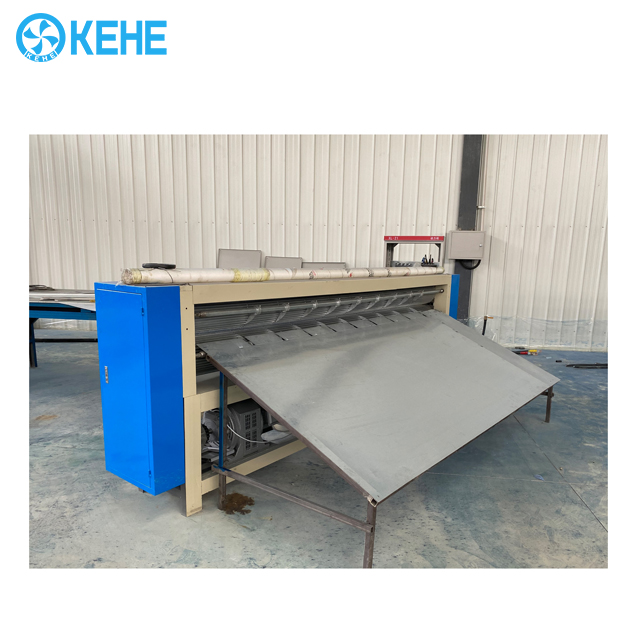

4.Gluing Machine with lifter |  | ||||||||

| 5.Oven Machine with press machine | ||||||||

6.Sawing Machine |

| ||||||||

| 7.Electrical Cabinet | ||||||||

Hot Tags: Cooling Pad Production Line

Previous

No InformationNext

No InformationSend Inquiry